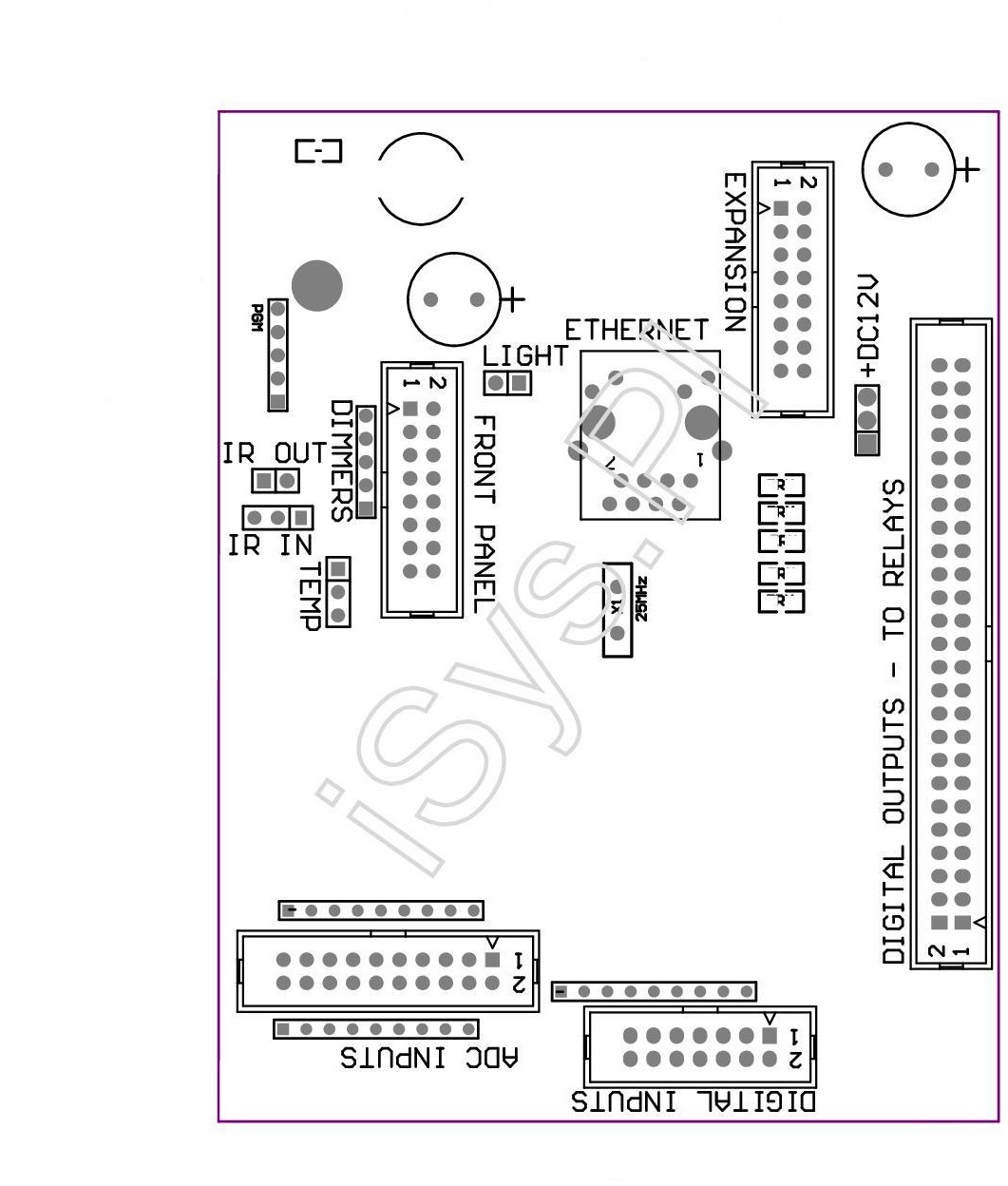

Ethernet eHouse – Smart home demonstration module, allows testing and evaluation of all the controllers of eHouse Home Automation.

Evaluation Module of eHouseEthernet building automation system contains all hardware resources (LEDs, Switches, Sensors) stored on the PCB replacing production installation at home.

Connection demonstration module to the controller is very simple and only requires connection of relevant “tapes” between the microprocessor controller and the demo PCB.

Ethernet Controllers can be divided into two main variants of the hardware:

- average controllers – based on EthernetRoomManager (ERM) PCB

- large controllers – based on CommManager/LevelManager (CM, LM) PCB

In this post we will discuss testing and evaluation of average controllers (based on ERM) module using Ehouse4Ethernet DEMO.

First, make sure that the power module is disconnected from demo and ERM has unconnected all the cables and connectors .

To fully analyze the behavior of the controller, you should connect the following ERM connectors between modules DEMO and ERM:

- Remove all cables from the connectors in the “TEST”

- 50 pin flat tape “outputs” (S18). And short the jumper “ERM Power” at the connector s18

- 14 pin flat tape “inputs” (S14) .

- 16 pin flat tape (S16) for the external panels of resources ERM (Infrared , temperature sensor , lighting , dimmers) .

- 20 pin flat table (J5) for Analog/Digital converters – Measurement.

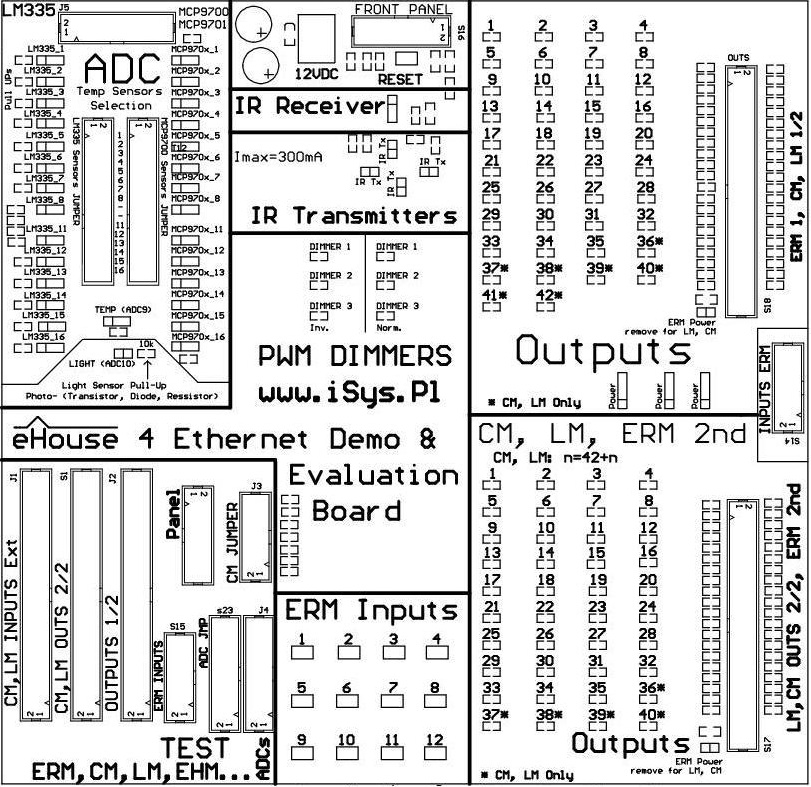

The next step is an appropriate combination of sensors connected to the inputs of the ADC .

For ERM, jumper “Light”, connecting light sensor to the ADC input of external panel of the controller .

For other controllers, it must be disconnected.

In addition, if the above sensors are connected, sensor selection jumpers require removal of jumpers for input 10 for the two 32-pin connectors .

If we are dealing with a controller other than the ERM and we need to connect temperature sensor MCP970x:

- Disconnect the jumper “Light”

- Connect jumper for input 10 on the 32 pin connector for LM335

- Or Connect jumper for input 10 on the 32 pin connector for MCP970x

The next step is to configure the remaining temperature sensors , connecting them to the required inputs .

Look for the 2x32pin, allowing the individual connecting of sensors LM335 or MCP970x to any input of controller.

You can select only one sensor for input.

Activation of the sensor also provides connection LM335 “Pull Up” resistor to 3V3 which provides power to the sensor.

This is a much more secure connection of the sensor than powered sensor circuit as the sensor pins are not touching power and there is not risk to overcurrent power supply.

LM335 Sensors for Ethernet controllers do not have the full-scale measurement and can measure temperatures up to about 56 degrees C.

In the case of very low temperatures may also have the effect of self-heating by the because it works with larger current, because these sensors are working optimally for 5V supply voltages.

For example, To connect the sensor to the input of LM335 No.7, in the 32-pin connectors remove the jumper in row 7 for MCP970x and short-circuit for LM335.

To connect the sensor to the input MCP970x No. 6 to the 32-pin connectors remove the jumper in row 7 for LM335 and close to MCP970x .

Be aware that, depending on the type of controller (hardware and interconnection module) part of the inputs can be connected on a printed circuit board of the controller to internal resources.

Please refer to the detailed documentation of the controller , measuring sensors that are not physically connected to other resources.

The next step is to connect the Ethernet (LAN) router or Switch to the eHouseEthernet controller RJ-45.

After checking and verifying that all cables are correctly connected and tightened 12VDC power supply can be connected to the module demo board which is also the powered from this.

Testing of Digital Outputs

States of the digital outputs are displayed on the LEDs located in the segment “OUTPUTS” of evaluation module.

LED lights for the corresponding output is equivalent to the turn on of a relay in production system.

Demonstration unit has two independent sections “OUTPUTS”, which allows simultaneous checking out two medium controllers (ERM , EHM , ESM , etc) .

This is particularly important if we want to associate the event with another controller sent from the first, and we intend to test it.

In order to avoid connection of an additional power cable, jumper “ERM Power” can be short in each section “OUTPUTS”.

Testing of Digital Inputs

The digital inputs of Ethernet controllers are connected via “Pull Up” resistors to the controller power supply (3V3) voltage.

It is necessary to activate the input by short to the ground.

Because of control events can come from a variety of sources , mono-stable switches are used (bell) to not collide with other signals and events issued.

The inputs are connected directly to the Ethernet module switches DEMO (“micro switch”) Is listed in “ERM Inputs” .

Pressing the switch on demo module is equal to include the switch to a production installation or activation sensor connected to coresponding input.

In special cases , input state can invert the application configuration CommManagerCfg.exe setting the flag “Invert” .

Event will be issued on disconnection the terminals from the ground .

This option should be used only in case of switches with normally-closed contacts NC (normally closed) .

This may for example refer to the reed confirming closing windows, door , gates , blinds or alarm sensors – Typical relay outputs which are normally connected (NC).

Misuse of options ” Invert ” the configuration of the input with respect to the type of switch is automatically running events associated with the start of each controller on or reset. In addition, normal switches will react with a delay, on release the switch and not on pressing them, as they should be .

The next step is to link system events associated with digital input.

This is done in the application CommManagerCfg.exe, by selecting an event from the list of events for a controller.

In the case of single input in select control event “Toggle” for Output would result in, each time you press the switch to change the state of the associated output.

You can also control a single output instead run programs. The program integrates any combination of the outputs of the digital outputs (on , off or leave unchanged) .

This will allow you to control complex light scenes consisting of a few/several independent lighting circuits with a few switches.

After configuring the digital inputs, press “Save Settings” on the main form to load the application to the controller.

Testing measurement sensors

After connecting and configuring the analog/digital converter input on demo module, what was discussed at the beginning of the post, propper sensor type must be set in the application configuration CommManagerCfg.exe for ADC input in for sensor.

Otherwise, the sensor value will be calculated in the wrong way by control panels software, and set invalid thresholds (eg . temperature) for running events will not make sense .

To change the type of sensor you must select “Advanced Settings” .

To test exceeds the thresholds (min, max) for a given input A/D converter, it is necessary to link the relevant event for (min , max) in the application CommManagerCfg.Exe.

Normally it turn on/off one of the outputs (to which in the production system device is connected to adjust a given physical level such as : heater, radiator valve, valve for floor heating in the room, etc. .)

In the case of heatting threshold (min) turn on and its stop in case of the threshold (max) turn off heater. This will allow you to achieve automatic control of the physical value (eg. temperature) and keeping it in the range (min, max).

It should also be noted, the setting of thresholds for all measuring inputs are grouped in A/D programs “ADC Settings” programs that integrate automated control of heating control, lighting, humidity, etc .

Taken into account are the thresholds for the currently running program.

When you enter configuration settings , measurement thresholds , ADC programs and loaded into the controller , so you should also run a configured A/D program.

Testing dimmers

The eHouse system use PWM/DC dimmers (pulse width modulation) to constant voltage power (eg 12VDC) .

They have a number of advantages such as light stepless, no flickering , changes in brightness, interference, hum , much higher frequency than 230VAC thyristor or triac dimmers .

EHouse dimmers are realized in hardware not a software so they are much faster and more accurate compared to other types of dimmers. They also do not burden the CPU and are not dependent on any other algorithms in the microprocessor controller. It grows dimmer precision many times and no brightness errors (changes , “swimming” ) appears .

In the dimmers section, there are LEDs to test different variants of dimmers .

On the demo unit there is three LED for dimmers that are typically incorporated into medium-sized controller modules

They are wired to the connector “Front Panel” (S16) .

There are 2 options for connecting LEDs to the controller in normal mode and invert.

In normal mode, the brightness of the dimmer is compatible (proportional y=a*x) to the level of a dimmer (0..255) in the controller .

The inverted brightness dimmer is opposed (ie inversely y=255-a*x where x= (0..255) to the level of the dimmer control .

Three dimmers can be used individually or as a single RGB dimmer in your home .

In a normal installation, instead of LEDs PWM controller optocoupler should be connected.

Depending on the specific controller PWM dimming LEDs transmit optocoupler connection in normal mode or reversed “compensates” dimmer type (normal or invert) .

Optocoupler is also very valuable because it isolates the power PWM dimming driver from the eHouse controller so it is much safer to connect without the need for a common voltage for controller and driver.

This is particularly applicable to the use of large amounts of PWM dimmers where it is impractical to use a single power supply for all dimmers and eHouse controllers.

When using low voltage dimmers such as 12V, it is not without significance, that the voltage drop at the cables. In the case of thin wires supply voltage from a single power supply voltage losses, may reach up to 50 % which means that in the final segments of the power supply voltage 12V dimmers instead we will have a 6V which will create ” phenomenon of the Christmas tree at home ” .

A better solution is to use several independent , “Local” low-voltage power supplies for dimmers .

This gives a much lower power dissipation as well as the price is often less and more reliable .

Provided security for automation is the use of voltage-isolated for separate control of external devices .

Testing Infrared Transmit and Receive – IR

Despite more modern control technology , graphic panels , smartphones – IR remotes control is still irreplaceable and unbeatable .

Local IR Control of room , TV , HiFi tower is much faster and more convenient .

In addition, the batteries can withstand many years rather than hours as for smartphones or tablets.

Pilots Prices are also considerably lower than the graphic panels, smartphones, etc. .

Wireless remote control and integration with Audio-Video systems, equipped with infrared support, EthernetRoomManager is implemented in several basic infrared standards .

EHouse4Ethernet demonstration module has built-in IR transmitter and IR receiver .

IR receiver allows you to receive signals from any of the pilots in the Sony SIRC standard enabling you to control the current EthernetRoomManager .

You can use it to:

- on/off/toggle outputs

- change the output program

- change the ADC program

- change the level of each dimmer

- reset the controller

- Launch event of any IR remote control codes assigned

- transmission of infrared codes to control software of executing other events and external functions

- infrared code scanning (learning) to control external devices TV , Audio / Video

- thresholds change the A/D (+ / – )

Infrared Transmitter is used to test of external devices, equipped with IR remote control.

To do so, the application “CommManagerCfg.exe” in IR settings “capture” IR code sent by pressing the button on the original remote control.

It will appear in the application window with the producer code.

You can then add name and store as a standard event of eHouse system and run in any way.

Testing and configuration of the Ethernet Module using the demo, before installing the controller modules in the rooms in the house is strongly advantageous, because then you do not have to run every time the remote control to the programmable controller, it is performed on a the table.

IR Learning time is also limited and is about 30 seconds, then the controller will automatically exit learn mode.

Infrared transmitter and receiver is also used in auto-Test for controllers.

For more information: Home Automation eHouse4Ethernet – Control room EthernetRoomManager.

Lighting Control , heating , HiFi equipment Home Automation eHouse4Ethernet – rollers, gates controller, alarm SMS alarm notification – CommManager .

eHouse4Ethernet Home Automation – controller floor, home, Apartment Lighting and heating control centralized version.